In the world of food, what’s on the outside is just as important as what’s on the inside. Proper food packaging is a critical element, serving as the first line of defense for product freshness, safety, and efficient supply chain management. It safeguards edibles from contaminants, physical damage, and environmental factors during their journey from production to the consumer’s table.

Let’s unwrap the different layers of food packaging:

1. Primary Packaging: The Direct Protector

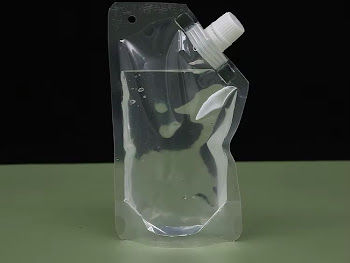

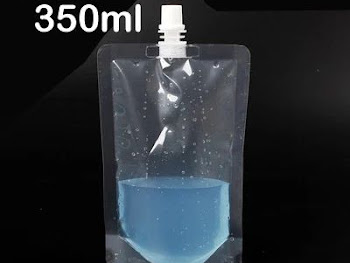

Primary PackagingPrimary packaging is the layer that directly encases the food product. Its primary role is to protect the food from spoilage, contamination, and damage, while also often displaying product information. The choice of material for primary packaging is crucial, balancing factors like preservation, cost, and environmental impact.

Common materials include:

- Plastics: Versatile, lightweight, durable, and cost-effective. They offer excellent barrier properties against moisture and oxygen, extending shelf life. However, their environmental impact due to non-biodegradability is a significant concern.

- Cellulose: Often used for wrappers or bags, offering breathability and biodegradability.

- Glass: Inert, non-reactive, and provides an excellent barrier, preserving taste and purity. It’s also recyclable and aesthetically pleasing. Its main drawbacks are fragility and weight.

- Metal: Used for cans and foils, offering high barrier protection against light, oxygen, and moisture, leading to long shelf lives for products. Metal is also recyclable.

- Paper/Paperboard: Lightweight and recyclable, commonly used for dry goods like flour or cereals, sometimes with inner linings for barrier properties.

3. Tertiary Packaging: The Logistics Enabler

Tertiary packaging is the outermost layer of packaging, designed for the efficient and safe transportation of products through the supply chain. Its primary function is to protect the secondary packaging from damage during handling, shipping, and warehousing. It’s vital for bulk transportation and logistical efficiency.

Common examples include:

- Cardboard Boxes: Large, durable boxes that hold multiple units of secondary packaging.

- Plastic Wraps: Used to secure and stabilize palletized goods.

The Importance of Labeling

Beyond the physical layers, clear and accurate labeling is an integral part of food packaging. Labels provide essential information to consumers, including ingredients, nutritional facts, expiry dates, and handling instructions. Advanced automated systems and direct printing technologies are increasingly being used to ensure efficient and precise labeling on various packaging materials.

Safety and Regulations

Food packaging is subject to stringent safety standards and regulations to ensure consumer well-being. Regulatory bodies, such as the FDA (Food and Drug Administration) in the United States, oversee the entire packaging process, from material selection to manufacturing practices. Manufacturers must adhere to strict guidelines regarding material safety and potential migration of substances into food. Innovations like metal detectors are often employed during the packaging process to prevent contamination and ensure product integrity.

Mastering the complexities of food packaging, from material science to regulatory compliance, offers manufacturers a significant competitive advantage in delivering safe, fresh, and appealing products to consumers.

Comment (1)

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.